�"Kit" might not be the best word to describe these products. They are shipped to you fully assembled, (except for electrical connections), so that you can go right to work adding your finishing touches. Leaving the armor and weapon up to you preserves maximum versatility and flexibility and it requires you to use your creativity to come up with a winning design. Start with this rugged, low-profile, mobile platform to simplify and reduce the time required to complete your project.

�The Middle and Heavy weight kits can be configured with two or four motors. Ether configuration will provide four-wheel drive. Robots with just two motors employ a "jack shaft" in place of the second set of motors. The jack shaft is simply a shaft with two sprockets that runs in two ball bearings mounted in the aluminum drive module. Four motors are required in the heavy weight kit if you choose to use the E30-150 economy motors.��

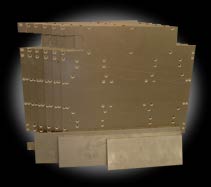

�The base plate is drilled and countersunk with all the holes required to mount one or two speed controllers, three sizes of batteries, and other components - a total of 92 holes.

�Features:

�Heavy-duty frames

�Light-weight base plates and bulkheads

�Complete drive trains

�Built-in motor and speed controller mounting

�Custom wheels

�Specs:

�Length: 30.0"

�Width: 24.0"

�Weight Bare: 43 lbs.

�Weight with two A28-400 motors, two MC-680 batteries, AmpFlow controller: 83 lbs

� �

�Rugged Construction

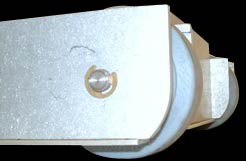

�BattleKits feature a bulletproof drive train that is completely housed in a square aluminum extruded tube.

�The one-piece extrusion (one each for the left and right drive trains), is precision CNC machined with mounting holes for all the sprockets, wheels, shafts, and motors. Each drive component is supported on both sides of the 3" x 3" square aluminum tubing to avoid "overhung" loads.

�The tubing is made from 6061-T6 aluminum alloy. The light weight robots have frame tubes with 1/4" wall thickness and the middle and heavy weights have tubing with 3/8" wall thickness.

� �

�Drive train modules include a separate two-stage speed reducer for each wheel. All the drive chains are continuous loops with no connecting links. (Connecting links reduce chain strength by almost 30%.) All BattleKits feature #35 chain. The sprockets, shafts, and axles are custom-made from 5140 Chromoly steel. Two different sets of sprockets are available so you have your choice of medium-fast or very fast. One of the powerful AmpFlow motors mounts on each drive module and is plenty strong for any ordinary robot. The middle and heavyweight drive modules also have mounting provisions for a second set of motors if you are looking for truly extraordinary acceleration.

� �

�The wheel assembly is made from the popular 4" Colson Performa tire. These are machined and mated to our custom hubs, bearings, and 19-tooth Chromoly sprockets. This combination weighs in at just 1.1 pounds - including the drive sprocket. We believe that this is the lowest-cost and lightest wheel/sprocket combination available. These wheels are included in all our kits but you can also order them separately. Visit our wheels section for more details.

� ��

��The base plates and the bulkheads are made from 6061-T6 aluminum. The base plates are drilled and countersunk with all the mounting holes for the bulkheads, drive modules, speed controller, and several different sizes and types of batteries. All components are CNC computer machined to tight tolerances for maximum consistency and lowest cost.

��One of the key features of these kits is that they are held together entirely with screws. Using screws instead of welding makes it easier to modify and repair. The heavyweight base plate has over 90 screw holes! The thickness of the base plates ranges from .156" for the heavy weight, down to .125" for the light weight. Bolting the bulkheads and the drive modules to the base plate results in a very stiff structure. You can easily drill and tap holes in the drive modules to mount your own custom components.

�None of the sprockets hang below the bottom surface of the drive modules - not even the sprockets on the wheels. The screws are all countersunk on the underside so nothing protrudes from the smooth surface of the base plate except the rubber part of the wheels.

��Battery Options and Mounting: We offer three different battery options. The batteries are held in place with steel mounting hardware that is bolted to the base plate. The base plates have been pre-drilled and countersunk for the hardware for each type of battery and for every optional battery location. Two inch wide Velcro strapping holds the batteries down onto the base plate. This combination of steel and Velcro makes for a very secure and low-cost mount while making it easy to remove the batteries for maintenance.

� ��

��Tip Resistance: The wheels are positioned so that they stick out of the frame towards the front and the rear. This allows the robot to be tipped up onto its front or rear and still maintain contact between the drive wheels and the floor. You can decide to keep this feature or cover the wheels. The wheels are also positioned as close to the sides of the frame as possible so that even sideways tips will still have to be quite extreme before the frame comes in contact with the floor.

��Another key feature is the low profile. The highest point on any of these kits (the bulkheads) is just 4.4 inches from the floor. This allows you plenty of room to mount your educational project or other devices on top of the kit's mobile platform without creating a robot that is unreasonably tall. A low center of gravity also makes it very difficult to tip the robot over.

��Ground Clearance: You can increase the ground clearance on any of our kits with a little extra machining. Contact us and we will provide detailed drawings.

��Reduction Ratios

�These drive modules are available with either 5.6 or 3.4 to 1 reduction ratios, (the same ratios used in our kits.) The standard ratio uses sprockets with 9 and 24 teeth and the high-speed ratio uses sprockets with 13 and 21 teeth. To switch to the faster ratio you just replace the standard sprockets with our high-speed sprockets.

�The following chart shows the robot's top speed using various combinations of motors and reduction ratios:

�� � | | � Motor RPM | � Standard 5.6 Ratio | � High Speed 3.4 Ratio | �

� � | A28-400 | � 4900 | � 10 MPH | � 17 MPH | �

� � | A28-150 | � 6000 | � 12 MPH | � 20 MPH | �

� � | F30-400 | � 4800 | � 10 MPH | � 17 MPH | �

� � | F30-150 | � 6900 | � 14 MPH | � 23 MPH | �

� � | E30-400 | � 5700 | � 11 MPH | � 19 MPH | �

� � | E30-150 | � 5600 | � 11MPH | � 19 MPH | �

�

�Ten to twelve MPH is plenty fast for almost any type of educational or fighting robot so we ship all our kits with the 5.6 reduction ratio. Those who have had lots of driving practice at that speed might want to try the faster ratio so we offer a high-speed upgrade.

�We recommend the following motors for use with the high speed ratio:

�Heavy weight kits: Four of the A28-400 or F30-400 motors

BK-BKT220��